Products for cast iron foundry

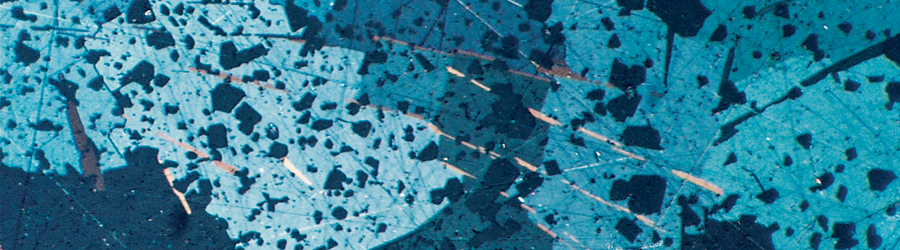

NODULARISERS

They are used to transfer their Mg content into the melt to promote the growth of carbon graphite spheres in the solidification phase.

- Ferro Silicon Magnesium (FeSiMg)

- Ferro Nickel Magnesium (FeNiMg)

- Nickel Magnesium (NiMg)

- Ferro Silicon Magnesium Lanthanum (FeSiMgLa)

- Cored wire

INOCULANTS

An operation aimed at increasing the number of eutectic cells in the phase prior to solidification, which solves numerous machinability problems of iron due to free carbides.

- Ferro Silicon (FeSi)

- Ferro Silicon Aluminum (FeSiAl)

- Ferro Silicon Strontium ( FeSiSr)

- Ferro Silicon Zirconium (FeSiZr)

- Ferro Silicon Zirconium Manganese (FeSiZrMn)

- Ferro Silicon Barium (FeSiBa)

- Ferro Silicon Barium + Cerium Mischmetal (FeSiBa 1% + CeMM)

- Ferro Silicon Lanthanum (FeSiLa)

- Ferro Silicon Barium Lanthanum (FeSiBaLa)

- Ferro Silicon Cerium (FeSiCe)

- Ferro Silicon Bismuth Cerium(FeSiBiCe)

- Inoculant cast in block for mould inoculation (Minoc A, Minoc M)

- Post inoculants

- Cored wire

CORRECTIVES

Correctives are used to fix the chemical adjustments of the metal load in the melt.

- Recarburizers in gray and ductile iron

- Ferro Manganese (FeMn)

- Ferro Silicon (FeSi)

- Silicon Carbide (SiC)

- FeSi briquettes

- FeMn briquettes

- SiC briquettes

- Cored wire

- Graphite Cored wire diam. 13 mm/16 mm

- FeSi Cored wire diam. 13 mm/16 mm

DESULFERIZERS

Desulferizers are used to reduce the amount of sulphur in the cast iron.

- Calcium Carbide (CaC2)

- Cored wire

PRECONDITIONERS

An operation aimed at removing the harmful effect of elements such as oxygen and derivatives from the cast iron melts and encourage inoculation in successive phases after pouring.

- Normalin®

Patented process for use in electric furnaces.

OTHERS

Complementary products to the manufacture of casts.

- Fluxes

- Filters

- Hoses